New Technology

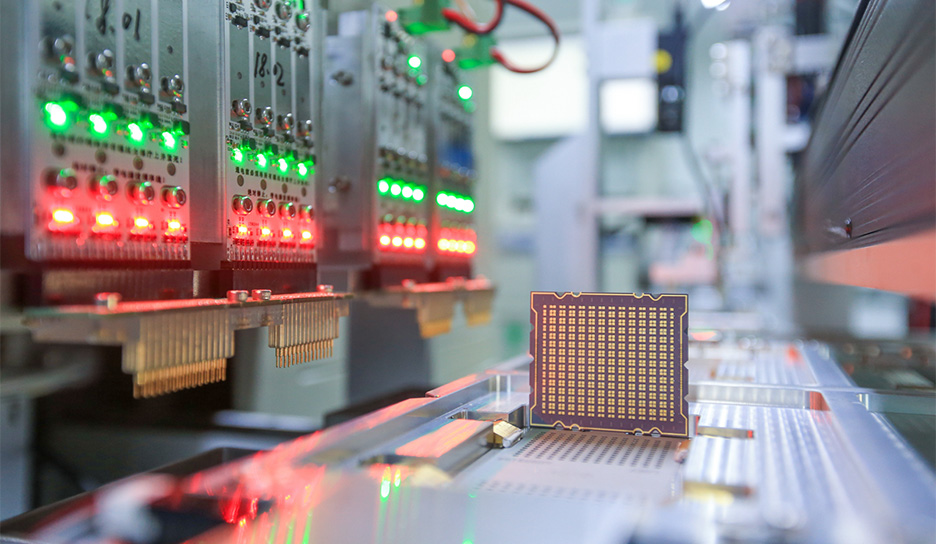

Our company utilizes advanced technology from various industries and fields to manufacture crystals and establish new product standards. We have obtained more than ten invention patents. For instance, we have developed mirror galvanometer and laser welding technology, which replaces traditional parallel welding, resulting in a 10-fold increase in production efficiency. We have also developed piezoelectric spray valves to replace traditional dispensing technology, increasing production efficiency by five times. Additionally, we have designed a sealed and purified track transportation system to replace clean rooms and manual handling, reducing operating costs. We have also developed visual inspection equipment to enhance deep learning capabilities, replacing manual quality inspection and reducing staff workload. Through continuous research and development, we have mastered core technology competitiveness and innovation.